Shaping equipments installed

The equipment below is installed and functional. Other devices, and in particular a mixer with a capacity of 1 L, as well as a granulation tool with a capacity of 2 kg, are in the process of being purchased.

A mixing-extrusion-spheronization apparatus

The Caleva Multilab is a device combining both a 10 to 20 g capacity mixer, a continuous single-screw extruder, and a spheronization plate. This apparatus is particularly suitable for shaping doughs with moderate viscosity, and makes it possible to obtain extrudates and grains of 0.5 to 3 mm in diameter.

A dual-screw extrusion apparatus

The Thermo Scientific Process 11 twin-screw extruder allows both continuous mixing and shaping of ceramic or hybrid powders, with controlled addition of powders and liquids along the extrusion sleeve by means of a screw gravimetric and peristaltic pumps, respectively. The scabbard and screws are made of X15TN steel, allowing a good compromise between abrasion resistance and corrosion resistance. The maximum working temperature is 350 ° C, and the maximum production rate is 2.5 kg / h.

The resulting extrudates have diameters varying between 0.5 and 3 mm, and shapes varying from cylindrical to trilobic.

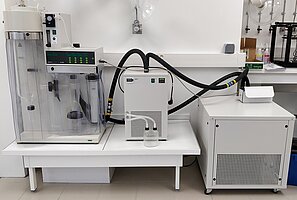

A spray-dryer

The Büchi B-290 drying atomizer allows both continuous drying of suspensions, but also to form fluidized grains, that is to say having sizes of the order of a few microns to tens of microns . The device is coupled to a dehumidifier and to an inerting loop, making it possible to work without releasing organic solvents into the room. The device can go up to 220 ° C in the atomization chamber, and has an evaporation capacity of 1 L / h of suspension.