Scientific and socio-economic context

The valorisation of biomass for the needs of chemistry and materials is a scientific topic in full development at the international level. Nevertheless, the industrial development of the biomass sector depends on the ability to develop new catalysts adapted to the treatment of specific molecules resulting from this abundant and renewable raw material, and presenting specificities distinct from conventional petroleum cuts (oxygen, impurities, etc. ).

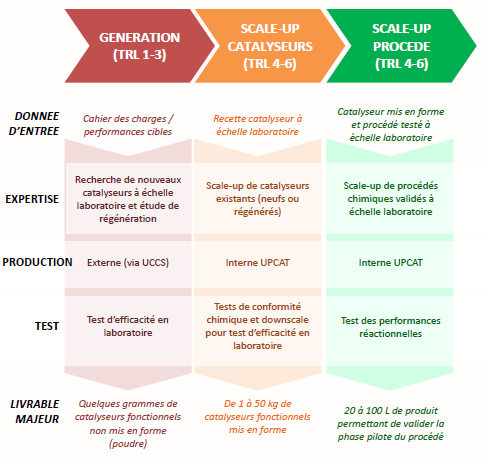

New generations of eco-designed catalytic systems are one of the keys to the development of new chemical processes with improved performance. However, the various scientific communities and in particular that of the biomass sector come up against a technological wall during the stage of transferring innovations to industry in a reasonable time, for lack of adequate infrastructure. A major challenge for these emerging catalytic systems is to integrate, from the stage of detecting promising materials in catalysis, the steps of scaling and production at a size and shape suitable for their use. These steps are indeed crucial and will make it possible to maintain greatly improved performance. In addition, the lack of standardized methods in a literature that is currently still scarce is another obstacle to their use on a pilot validation scale.

UPCAT objectives

The UPCAT technological cluster enables academic and industrial players to obtain competitive advantages linked to tits capacity for innovation and responsiveness. Thus, the latter will be able, particularly at national and European level, with certain industrial innovations (new products), to position themselves as major players in the bioeconomy. The objectives are broken down into two main aspects:

Scientific objectives :

- Acquisition of know-how in the field of scaling catalyst syntheses (supports, active phases, mixed oxides, inorganic materials - hybrids - organic), and allowing to rationalize the innovative syntheses of academic laboratories to be able to produce several kilograms of materials.

- Control and understanding of the fundamental phenomena involved during the shaping stages of catalytic materials, covering a wide range of shapes and sizes. This will allow the cluster to be able to offer a broad and flexible service offering.

- Ability to control and validate extrapolated materials, both from a physicochemical point of view (structure, texture, mechanical and chemical resistance) and from a reaction point of view.

- Develop high-level expertise in understanding the deactivation and regeneration mechanisms of catalytic materials, as well as their ultimate recycling.

Socio-economic objectives :

- Increase the responsiveness of research to changing demands and the market; with the support of the cluster, manufacturers will have the opportunity to develop their products quickly, efficiently, and in accordance with the constraints of ecodesign.

- Securing of processes and their monitoring; UPCAT will be able to monitor specific processes. Direct monitoring of the processes will induce improved reactivity / safety in production for the requesting manufacturers, and in particular for small companies that do not generally benefit from an internal R&D service.

Flexibility of products and volumes from the cluster; in connection with its structure and its ability to supply materials, products, custom processes, etc. according to the fundamental research demands of the various manufacturers. - Ensure eco-efficient products and processes; due to the requirements initially established by the cluster, and imposing, in its foundation, the development of eco-efficient processes (carbon footprint, energy consumption, bio-based / abundant and non-toxic raw materials, etc.).

- Flexible and tailor-made offer; not provided by the academic world, nor by manufacturers in the field, and ideal for helping the development of large groups as well as very small businesses and SMEs. The major players in the field will thus be able to use UPCAT for materials, their shaping, and even only for scaling up production of a material already designed. For VSEs and SMEs, not having comparable financial capacities, and therefore unable to develop a product internally, an academic research partnership with UPCAT will enable them to obtain a turnkey process, with associated scientific and technical monitoring.